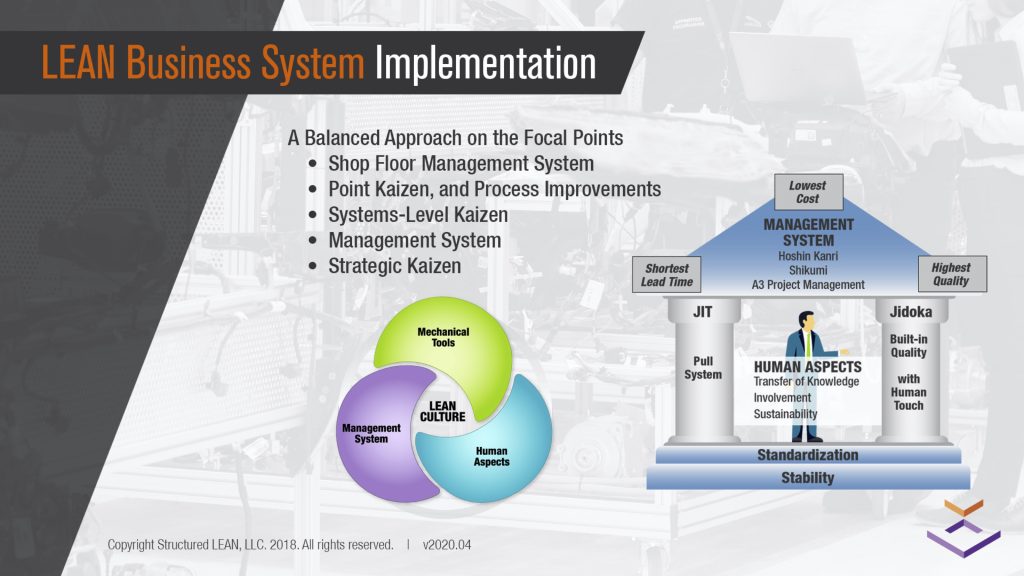

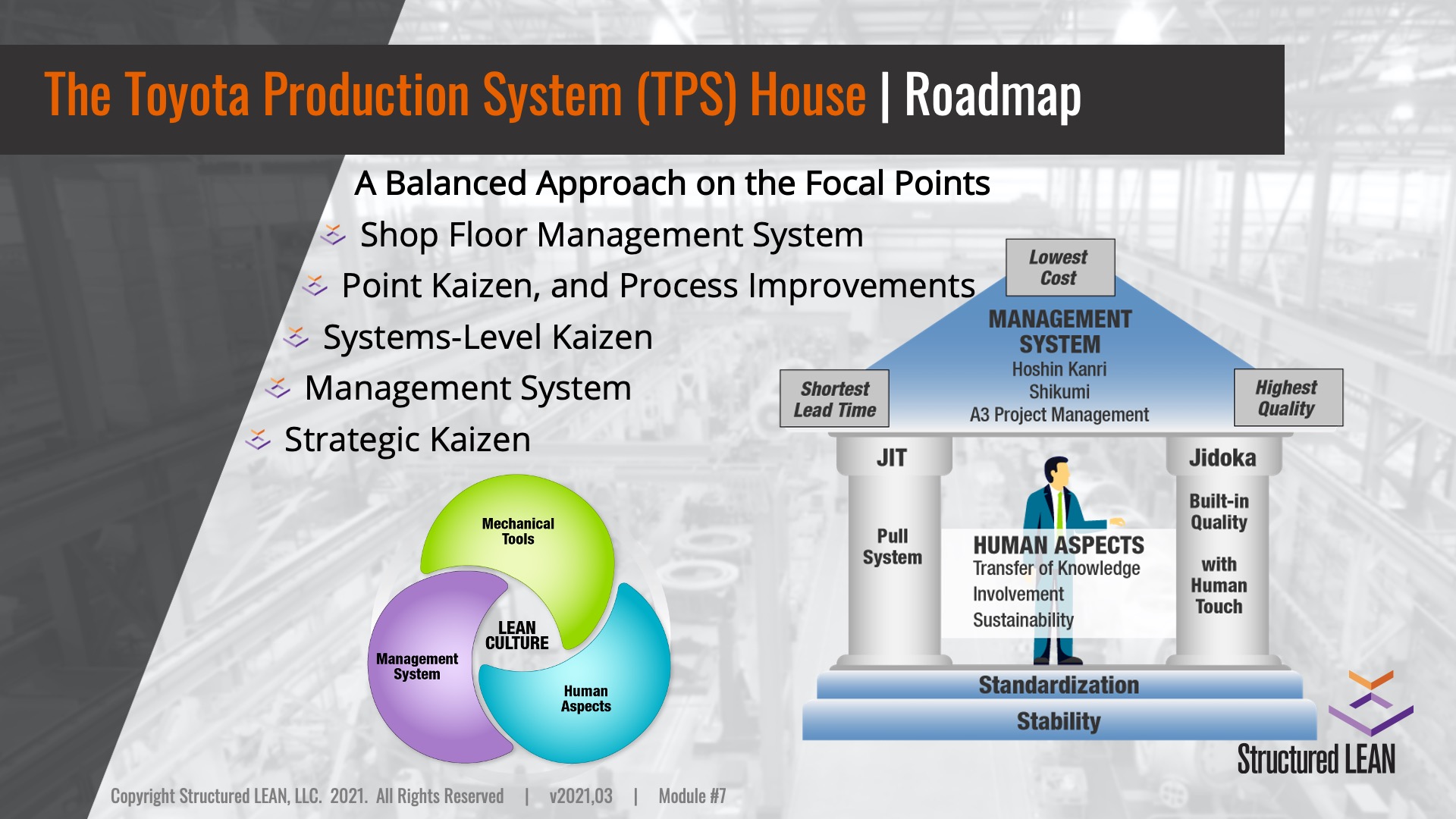

The Toyota Production System (TPS) House is a common visual tool used to describe the LEAN Business System and the five (5) Focal Points for its implementation. But what does it really mean? And how does it apply to your program efforts?

In order to put a framework around your knowledge and understanding, we will explain the basic principles that the TPS House refers to… including how it is reflected in everything that we do!

The Toyota Production System (TPS) House

TPS is visually represented as a house because this easily conveys the model from which the Business System operates.

The Foundation: Stability and Standardization

Stability is producing consistently on a day-by-day (or normal routine) basis. It also consists of your ability to control your process variation in a predictable manner.

Standardization is where processes and procedures are defined and followed. It also includes how the machines are operated, as well as where the materials and tools are placed.

Stability and Standardization represent the basis for all other improvement activities of a LEAN Business System.

Jidoka is referred to as Built-in Quality. This means the Highest Quality is “built-in” at the first possible source. The underlying meaning is that the design of the process itself, has Quality “built-in” from the start.

The Second Pillar: JIT (Just-in-Time)

JIT refers to Just-in-Time Production. This means production of what the Customer wants, when they want it, in the quantities requested. The underlying meaning is that products are made to order, and not built to stock or inventory.

The Management System refers to the way in which your company’s business objectives (in the form of KPIs) are achieved through the Business System.

Human Aspects: Transfer of Knowledge

Respect for People aims to achieve trust and mutual understanding.

It is also the responsibility to combine the power of individual employees… Toyota refers to “this attitude as regarding people’s ability to think most”.

The Roadmap for Implementation: The Focal Points for Implementing a LEAN Business System

The Blueprint of the TPS House is your Roadmap for Implementing the Focal Points of a LEAN Business System.

By achieving something similar, your company will establish a Competitive Advantage that will distinguish your company from your competitors, which will ultimately lead to success!

Quick Reference Guide, 1-Pager

Review our 1-Page, Quick Reference Guide explaining The Toyota Production System (TPS) House.

Reflection Questions, for Lessons Learned

Questions to think about and reflect upon, so you may develop your own Lessons Learned.

The Focal Points for Implementing a LEAN Business System

Learn more about how to apply Our Balanced Approach by implementing the Focal Points of a LEAN Business System. The five (5) Focal Points include: 1) Shop Floor Management System; 2) Point Kaizen, and Process Improvements; 3) Systems-Level Kaizen; 4) Management System | Structure; and 5) Strategic Kaizen.

Learn about all of the different Focal Points, and how they are integrated with one another for an effective implementation. Also see why our efforts focus on the Systems-Level Kaizen, and why this blueprint will drive a comprehensive approach for your program.

The Integration of Business Objectives/KPI Deployment and Visual Controls in order to Facilitate Problem-Solving and Team Work

Point Kaizen, and Process Improvements

Utilizing the Multitude of Tools that are Available to Improve a Single Process or Work Cell

Focusing on the Connected Processes in order to Improve the Complete Business System Across ALL of the Functions within the Organization

Providing the Structural Elements to Achieve the Desired Business Objectives/KPIs in a Sustainable Way

Focusing on the Development of the Roadmap, and Implementation of the Complete Business System