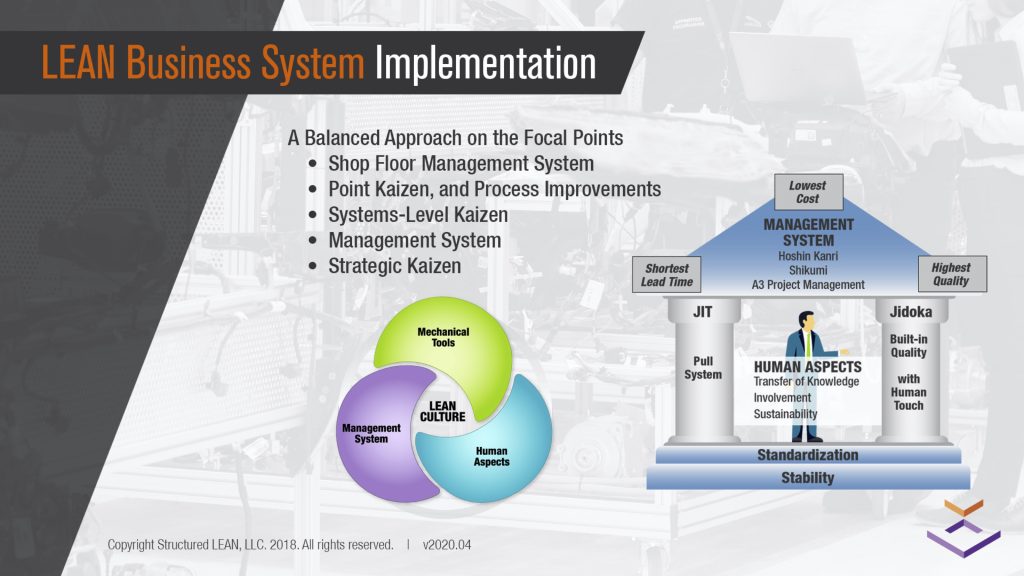

Most LEAN programs fail to sustain and achieve long-term results – sound familiar? The simple answer has to do with little to no focus on implementing the complete LEAN Business System. And in order to implement this, your program must have a balanced approach with three (3) core elements: 1) the Mechanical Tools; 2) the Management System; and 3) Human Aspects.

Most program efforts only focus on the Mechanical Tools, because they are relatively straight-forward and you can quickly see evidence of tangible results…

Come learn about the other elements, and why their interdependence on one another will allow your program to truly achieve your long-term desired results!

Our Balanced Approach for Implementation

Explain and Apply the Concepts and Methods

Build the Structure for Long-Term Sustainability

Develop the Organizational Capabilities

Culture Drives Results

Our Balanced Approach for LEAN Culture

Learn more about our explanation for Our Balanced Approach and the background information for LEAN Culture.

Quick Reference Guide, 1-Pager

Review our 1-Page, Quick Reference Guide explaining Our Balanced Approach for Implementation.

Reflection Questions, for Lessons Learned

Questions to think about and reflect upon, so you may develop your own Lessons Learned.

The Focal Points for Implementing a LEAN Business System

Learn more about how to apply Our Balanced Approach by implementing the Focal Points of a LEAN Business System. The five (5) Focal Points include: 1) Shop Floor Management System; 2) Point Kaizen, and Process Improvements; 3) Systems-Level Kaizen; 4) Management System | Structure; and 5) Strategic Kaizen.

Learn about all of the different Focal Points, and how they are integrated with one another for an effective implementation. Also see why our efforts focus on the Systems-Level Kaizen, and why this blueprint will drive a comprehensive approach for your program.

The Integration of Business Objectives/KPI Deployment and Visual Controls in order to Facilitate Problem-Solving and Team Work

Point Kaizen, and Process Improvements

Utilizing the Multitude of Tools that are Available to Improve a Single Process or Work Cell

Focusing on the Connected Processes in order to Improve the Complete Business System Across ALL of the Functions within the Organization

Providing the Structural Elements to Achieve the Desired Business Objectives/KPIs in a Sustainable Way

Focusing on the Development of the Roadmap, and Implementation of the Complete Business System